Diecasting has developed itself as an important manufacturing procedure in Malaysia, driving development throughout various markets such as auto, electronics, and durable goods. By using molten metal infused right into steel mold and mildews under high pressure, diecasting develops components that are not just specific however also very durable. Malaysia’s position as a critical production hub in Southeast Asia, incorporated with its competent labor force and progressed framework, has actually made it a recommended destination for diecasting solutions. The nation’s manufacturers are identified for their commitment to top quality, development, and sustainability, making Malaysia an important player in the worldwide supply chain. As industries remain to demand light-weight and complicated elements, Malaysia’s diecasting industry is positioned for sustained growth.

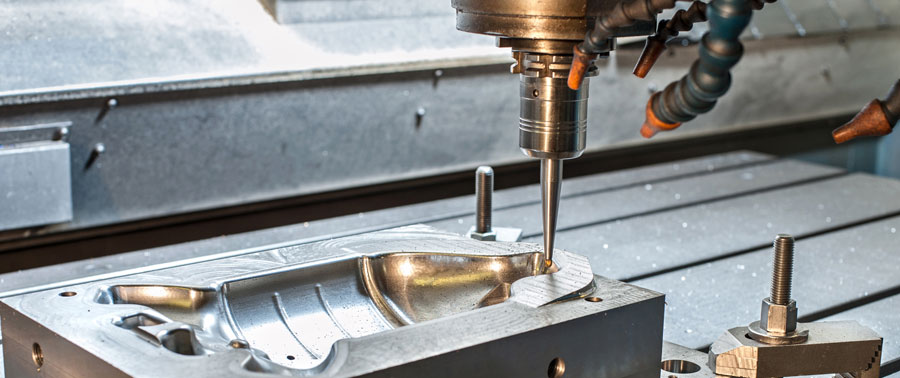

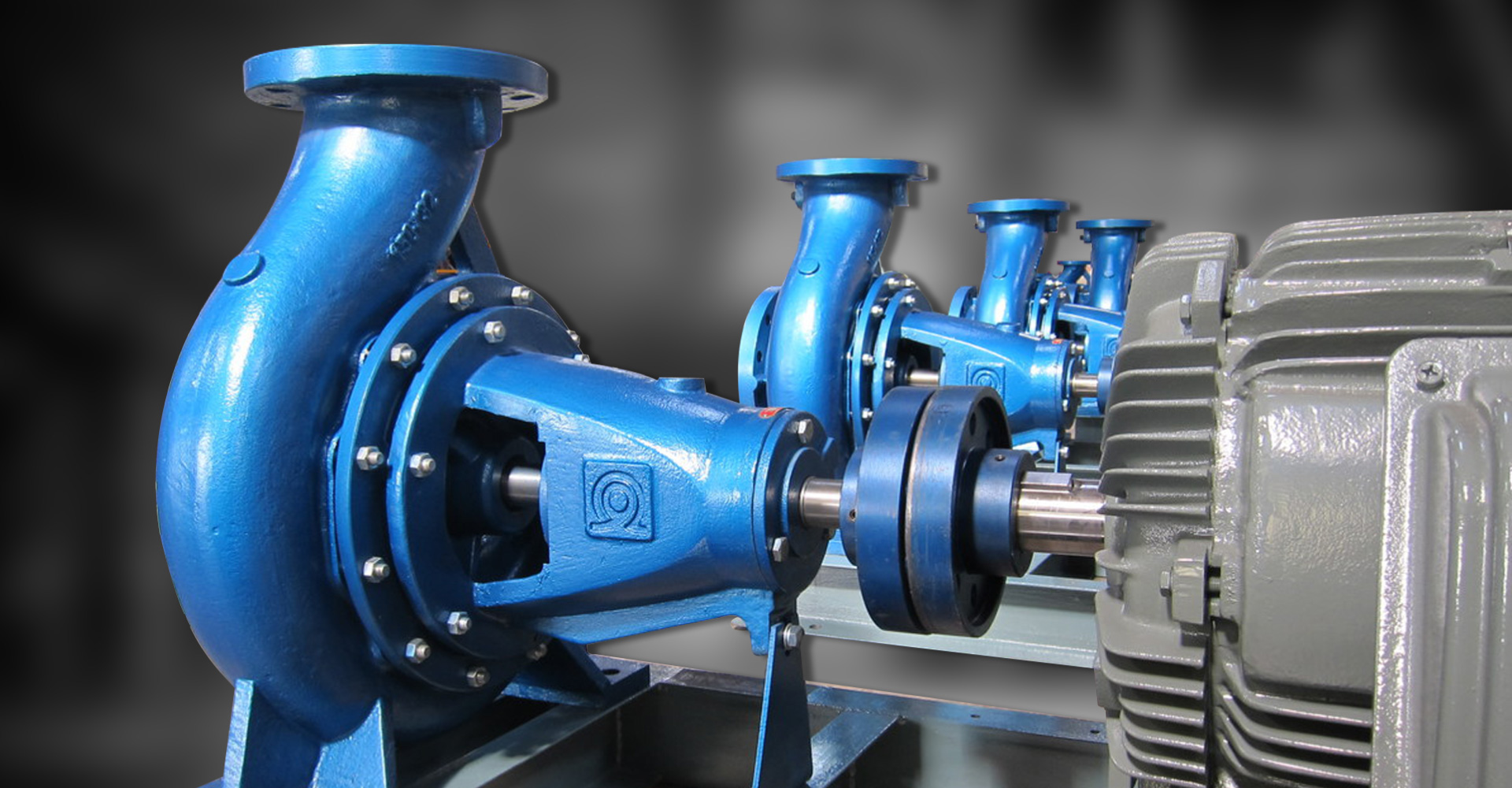

One of the main factors Malaysia excels in diecasting is its capacity to create premium components tailored to fulfill the demands of various fields. Diecasting uses a level of precision that is unmatched by many various other production methods, enabling Malaysian manufacturers to produce complex layouts and tight tolerances. Aluminum, zinc, and magnesium are the most typically made use of materials, valued for their lightweight residential or commercial properties and structural honesty. In the automotive field, for instance, diecast elements such as engine blocks, gearboxes, and brackets are important for decreasing vehicle weight and improving gas efficiency. Malaysian manufacturers have positioned themselves as leaders around, providing diecast components to significant international car manufacturers and Tier 1 suppliers.

The electronic devices industry in Malaysia additionally profits considerably from the regional diecasting sector. The ability to produce thin-walled, intricate elements is critical for electronic gadgets where space and weight are major considerations. Warmth sinks, enclosures, and adapters made via diecasting play a pivotal role in maintaining the performance and reliability of customer electronics and telecoms tools. Malaysia’s expertise in precision design makes certain that these parts meet strict quality criteria called for by international modern technology brand names. As demand for electronic devices remains to increase, Malaysian diecasters are positioned to play an important role in supporting the fast development of this industry.

Sustainability is one more defining attribute of diecasting in Malaysia, as the sector adopts environmentally friendly techniques to minimize its environmental impact. Diecasting is inherently effective, with minimal product waste due to the recyclability of steels such as aluminum and zinc. Malaysian manufacturers are taking this a step additionally by implementing energy-efficient innovations, such as advanced melting heaters and computerized production lines, to decrease power consumption. Closed-loop recycling systems are likewise being taken on, making certain that scrap product is recycled and reused within the production cycle. These initiatives not only straighten with worldwide sustainability goals but also enhance Malaysia’s competition in the global market, where eco-conscious techniques are increasingly prioritized. For more information please visit here Senadiecasting

The growth of diecasting in Malaysia has been supported by government campaigns that encourage technology and skill development. Programs such as tax obligation motivations for technology adoption and grants for r & d have made it possible for producers to purchase advanced equipment and automation. At the same time, cooperations with technical organizations and colleges have actually assisted grow a proficient workforce skilled in operating modern equipment and preserving production high quality. This mix of technological improvement and human experience has actually enabled Malaysian diecasters to continue to be competitive in a rapidly advancing industry, attracting clients from around the globe.

Diecasting in Malaysia is a testament to the country’s stamina in precision manufacturing, delivering high-grade elements that satisfy the requirements of diverse markets. Its capacity to create light-weight, intricate, and long lasting components has actually made it a cornerstone of the automobile and electronics industries. By embracing sustainability and leveraging advancement, Malaysia’s diecasting market remains to solidify its credibility as a reliable and forward-thinking player in the international supply chain. With increasing need for high-performance elements and eco-friendly remedies, Malaysia’s diecasting market is set to play an even higher function fit the future of manufacturing.

Leave a Reply